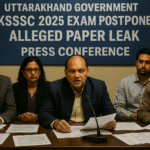

JSW Cement IPO 2025: What Investors Should Know Amid Industry Headwinds

JSW Cement plans to launch an IPO in 2025 as part of its aggressive expansion strategy. But as the MD candidly admits, JSW currently doesn’t have the capacity to challenge giants like Adani or Birla immediately. Here’s a full analysis of the IPO, valuations, risks, and outlook.

Table of Contents

Executive Summary

JSW Cement Limited, a subsidiary of the diversified JSW Group, is preparing for an initial public offering expected in the fourth quarter of 2025. The company currently operates approximately 40 million tonnes per annum (MTPA) of cement manufacturing capacity across facilities in Karnataka, Maharashtra, Odisha, and Andhra Pradesh. This positions JSW as a mid-sized player in India’s cement industry, which has total installed capacity of approximately 450-470 MTPA.

Recent statements from Managing Director Parth Jindal have drawn significant attention for their candid assessment of JSW Cement’s competitive standing. The leadership acknowledged substantial gaps separating the company from industry leaders including UltraTech Cement and Adani Cement. This transparent communication approach contrasts with typical corporate messaging and has generated considerable discussion among market participants.

The planned IPO aims to raise capital for capacity expansion, debt reduction, and working capital requirements. Analysts project an issue size between ₹3,000-4,000 crore with expected valuation multiples of 10-12x enterprise value-to-EBITDA. The offering will provide investors exposure to India’s cement sector growth while presenting execution risks inherent in aggressive expansion strategies.

Last Updated: August 05, 2025

JSW Cement Background and Operational Overview

Company Formation and Strategic Development

JSW Cement Limited was established in 2019 as part of the JSW Group’s strategic diversification into building materials. The JSW Group has built its primary reputation through steel manufacturing operations, which remain the conglomerate’s largest business segment by revenue and profitability.

The cement division represents a deliberate expansion into complementary building materials. This vertical integration strategy allows the group to serve construction and infrastructure customers across multiple product categories. The decision to enter cement manufacturing reflected management’s assessment of attractive long-term demand dynamics in India’s construction sector.

Since inception six years ago, JSW Cement has pursued geographic expansion across southern and western India. Manufacturing facilities have been strategically positioned in states experiencing robust infrastructure development and urbanization. The company has established operations spanning Karnataka, Maharashtra, Odisha, and Andhra Pradesh.

Current installed capacity stands at approximately 40 MTPA distributed across multiple manufacturing plants. This capacity includes both integrated cement plants with captive clinker production and grinding units that process clinker into finished cement products. The geographic distribution of facilities aims to optimize logistics costs while serving high-growth regional markets.

Manufacturing Footprint and Capacity Distribution

JSW Cement’s manufacturing facilities incorporate modern production technology and equipment. Newer plants benefit from contemporary design standards, enabling competitive energy efficiency and operating cost structures. The company has invested in pollution control systems and environmental management practices aligned with increasingly stringent regulatory requirements.

Clinker production capacity represents a critical component of the manufacturing footprint. Clinker, the binding ingredient in cement, requires dedicated production facilities with access to limestone deposits. Companies with captive clinker capacity enjoy cost advantages over manufacturers dependent on purchasing clinker from external suppliers, particularly during periods of tight supply.

The company has secured limestone mining leases in proximity to manufacturing facilities. These mining operations ensure consistent raw material availability while minimizing transportation costs. Limestone quality and reserve longevity significantly influence long-term manufacturing economics and facility viability.

Logistics infrastructure supporting cement distribution includes rail sidings, bulk handling facilities, and regional grinding units. Cement is a high-volume, low-value commodity where freight costs substantially impact delivered pricing and competitive positioning. Investments in logistics infrastructure aim to compress distribution costs and expand economically viable market reach.

Product Portfolio and Market Positioning

JSW Cement manufactures multiple cement varieties addressing different customer segments and application requirements. The product portfolio includes Ordinary Portland Cement (OPC), Portland Pozzolana Cement (PPC), and Portland Slag Cement (PSC). Each variant serves specific construction applications with distinct performance characteristics.

Premium specialty cements command price premiums over commodity-grade products. Segments including high-performance construction cement, rapid-setting formulations, and specialty applications for coastal environments offer margin enhancement opportunities. JSW has invested in manufacturing flexibility enabling production across product categories based on demand patterns.

Brand positioning emphasizes quality, technical support, and reliability. The company targets both bulk institutional customers including large construction contractors and infrastructure project developers, as well as retail distribution through dealer networks serving individual builders and small contractors. Balancing these channels requires distinct go-to-market strategies and customer engagement approaches.

Leadership Perspective: Parth Jindal’s Transparent Assessment

Candid Commentary on Competitive Position

Managing Director Parth Jindal’s recent public statements have generated considerable industry discussion for their uncommon directness regarding JSW Cement’s competitive standing. During a media interaction, Jindal acknowledged that JSW currently lacks the capacity to directly compete with industry giants including Adani Cement and the Birla Group’s cement operations.

The remarks included the specific phrase that JSW “doesn’t have the aukaat”—a Hindi term translating to capacity, capability, or stature—to challenge these established leaders at present. This frank admission represents a departure from conventional corporate communication, which typically emphasizes competitive strengths while minimizing acknowledged weaknesses or gaps relative to peers.

The transparent assessment serves multiple strategic communication objectives. First, it establishes realistic expectations among prospective investors regarding JSW’s current market position and near-term competitive trajectory. This reduces risk of valuation inflation based on overly optimistic growth projections or market share gain assumptions that may prove unsustainable.

Second, the statement signals management’s preference for measured, organic growth over aggressive acquisition-driven expansion. In an industry experiencing consolidation, with larger players acquiring regional manufacturers to rapidly scale capacity, JSW’s approach emphasizes building operations rather than buying market position through potentially overpriced acquisitions.

Strategic Implications of the Commentary

Jindal’s remarks reveal important insights into JSW’s strategic planning and decision-making framework. The acknowledgment of current scale limitations across key dimensions—production volume, market presence, distribution network density, and brand recognition—demonstrates realistic self-assessment rather than strategic denial.

Simultaneously, the commentary signals fiscal discipline regarding capital deployment. Management appears cautious about overpaying for acquisition targets in a fragmented market where asset valuations may not reflect sustainable earning power. This approach may sacrifice short-term growth velocity but potentially delivers more sustainable long-term value creation through operational excellence.

The measured growth strategy reflects lessons observable from companies that expanded too rapidly through mergers and acquisitions. Rushed consolidation often inherits operational inefficiencies, integration challenges, and overvalued assets that subsequently erode shareholder returns. JSW’s explicit preference for organic development suggests management awareness of these pitfalls.

The transparent communication style may also reflect generational shifts in corporate leadership and messaging approaches. Younger executives like Parth Jindal often demonstrate greater comfort with direct, authentic language over traditional polished corporate communications. This approach may resonate particularly with millennial and Gen-Z investors who increasingly value transparency.

IPO Rationale and Capital Deployment Strategy

Primary Objectives of the Public Offering

JSW Cement’s decision to pursue initial public offering in late 2025 stems from specific capital requirements tied to its multi-year expansion strategy. The IPO addresses three interconnected financial objectives that will shape the company’s development trajectory through 2027 and potentially beyond.

The public offering will enable the company to access equity capital markets, diversify its shareholder base beyond JSW Group ownership, and establish public market valuation. Listed status provides enhanced credibility with customers, suppliers, and lenders while creating liquidity for existing shareholders and future capital raising flexibility.

The timing reflects management’s assessment that current market conditions, company operational scale, and growth trajectory align favorably for successful public market entry. Market receptivity to cement sector offerings, overall equity market sentiment, and competitive positioning relative to recent comparable IPOs all influence optimal listing timing.

Funding Greenfield Capacity Expansion

The primary capital deployment involves financing new manufacturing facilities, clinker production units, limestone mining lease acquisitions, and supporting logistics infrastructure. Cement manufacturing requires substantial upfront capital investment, with modern integrated facilities typically costing ₹200-300 crore per million tonne of annual capacity.

JSW’s expansion plans include commissioning greenfield plants in strategically selected locations where multiple factors converge favorably. Site selection criteria include limestone reserve access, proximity to demand centers, logistics connectivity, water availability, and regulatory environment. Identifying locations optimizing these variables requires extensive geological surveys, market analysis, and feasibility studies.

Clinker capacity expansion represents particularly critical investment priority. Captive clinker production provides significant cost advantages over dependence on merchant clinker procurement. Companies with integrated clinker operations control their supply chain more comprehensively while benefiting from superior economics, especially during periods of tight clinker availability or price volatility.

Limestone mining lease acquisition secures long-term raw material access. Limestone quality directly impacts manufacturing efficiency and cement quality. Securing reserves proximate to manufacturing facilities minimizes freight costs, a significant operating expense given limestone’s bulk. Regulatory clearances for mining operations have become increasingly complex, making early investment in lease acquisition strategically valuable.

Logistics infrastructure investments address last-mile delivery economics that significantly impact competitiveness. Cement’s high-volume, low-value characteristics mean freight costs materially affect delivered pricing. Strategic investments in rail connectivity, captive truck fleets, regional grinding units, and bulk handling facilities can reduce logistics costs by 15-20%, translating directly to either margin improvement or competitive pricing flexibility.

Balance Sheet Deleveraging and Financial Optimization

The second IPO objective involves reducing leverage accumulated during initial expansion phases. Capital-intensive industries like cement typically carry significant debt during growth periods, particularly when funding large manufacturing projects with multi-year construction timelines and utilization ramp-up periods.

Elevated leverage constrains strategic flexibility during industry downturns or unexpected operational challenges. High debt levels increase financial risk, elevate interest costs that erode operating margins, and limit capacity to pursue opportunistic investments. Credit rating agencies closely monitor leverage ratios, with excessive debt potentially triggering rating downgrades that increase future borrowing costs.

By raising equity capital through the IPO, JSW can retire expensive debt, reduce interest burden, and improve credit metrics. Balance sheet deleveraging signals financial prudence to institutional investors who scrutinize debt-to-equity ratios when evaluating capital-intensive manufacturers. Companies maintaining conservative leverage typically command valuation premiums as they demonstrate lower financial risk.

The targeted debt reduction aims to bring net debt-to-EBITDA ratio below 2.5x from current estimated levels around 3.5-4.0x. This improvement would align JSW’s leverage with industry best practices while preserving debt capacity for future growth investments. Interest coverage ratios would similarly strengthen, providing greater cushion during potential industry downturns.

Equity Capital for Sustainable Growth Trajectory

The third objective involves bolstering equity capital to maintain comfortable leverage ratios while preserving financial flexibility for future investments. Even as absolute debt levels decline through partial retirement, ongoing capacity expansion requires continuous capital allocation. Adequate equity capital ensures the company can pursue growth opportunities without exceeding prudent leverage thresholds.

This capital structure management reflects sophisticated financial planning rather than reactive crisis response. Instead of oscillating between high leverage periods followed by distressed equity raises, JSW aims to establish balanced capital structure supporting consistent investment capacity across business cycles.

Working capital requirements will also receive partial funding from IPO proceeds. Cement distribution involves extending trade credit to dealers, maintaining finished goods inventory, and managing raw material stocks. Aggressive distribution network expansion requires incremental working capital deployment to support growing receivables and inventory balances.

Competitive Landscape and Market Position Analysis

Installed Capacity Comparison with Industry Leaders

JSW Cement’s current 40 MTPA capacity positions it as a mid-sized national player, substantially behind industry leaders. Understanding these capacity differences reveals the scale challenges JSW faces in achieving competitive parity with established manufacturers.

UltraTech Cement, India’s largest manufacturer and a subsidiary within the Aditya Birla Group, operates approximately 140 MTPA of annual capacity. This massive scale results from decades of organic expansion supplemented by strategic acquisitions including Jaiprakash Associates’ cement assets and Century Textiles’ cement division. UltraTech’s capacity provides unmatched purchasing power for raw materials, coal, and consumables, along with extensive distribution reach covering virtually every significant Indian market.

Adani Cement has rapidly scaled to approximately 78 MTPA capacity through aggressive organic expansion and transformational acquisitions. The landmark purchase of Holcim India’s assets added substantial capacity and market presence. The Adani Group’s broader infrastructure capabilities, including captive logistics networks, port facilities, and power generation operations, create meaningful synergies enhancing cement operations.

Shree Cement operates around 47 MTPA capacity with industry-leading operational efficiency metrics. The company has historically achieved superior EBITDA margins through focus on manufacturing excellence, energy efficiency, and cost management. Shree Cement’s profitability demonstrates that scale alone doesn’t determine success, though operational efficiency at scale provides maximum competitive advantage.

Dalmia Cement controls approximately 35 MTPA capacity with strong positioning in eastern and southern India. Birla Corporation, distinct from UltraTech despite shared Birla family lineage, operates approximately 18 MTPA capacity concentrated in eastern regions. These capacity figures reveal JSW’s challenge—at 40 MTPA, the company holds roughly 8-9% market share in an industry where top five players control over 60% of national capacity.

Distribution Network and Market Reach Disparities

Beyond manufacturing capacity, distribution network density creates perhaps even more significant competitive moats that prove difficult for newer entrants to overcome. Cement distribution requires extensive infrastructure encompassing dealer relationships spanning multiple decades, sophisticated trade credit management systems, brand visibility among construction professionals and retail buyers, and logistics coordination capabilities.

UltraTech and other established leaders have invested decades building distributor networks spanning metropolitan cities, tier-2 and tier-3 towns, and even rural markets with construction activity. These networks involve complex relationship management, inventory positioning, and dealer support programs that cannot be replicated quickly regardless of capital availability.

JSW’s distribution network, while expanding steadily, remains concentrated in its core southern and western operational geographies. Establishing national distribution presence requires years of relationship building with dealers, extended trade credit deployment to incentivize dealer partnerships, and sustained brand development. These investments don’t immediately translate to revenue or market share gains, requiring patient capital and management persistence.

Dealer economics play crucial roles in distribution network development. Established manufacturers typically offer dealers margins of 3-5% on cement sales plus volume-based incentives and credit support. New entrants must often provide enhanced economics to incentivize dealers to carry additional brands, creating margin pressure during market penetration phases.

Brand Recognition and Customer Preference Patterns

In cement marketing, brand recognition among contractors, builders, civil engineers, and construction project managers significantly influences purchasing decisions. This effect proves particularly pronounced for premium products and large infrastructure or commercial construction projects where performance reliability outweighs pure price considerations.

Established brands benefit from decades of performance history, accumulated technical support relationships, and word-of-mouth recommendations within construction communities. Engineers and architects specifying cement for projects often default to known brands with proven track records, creating specification inertia that favors incumbents.

JSW’s relatively recent market entry means limited brand equity outside its home markets. The JSW Group name carries recognition in steel and infrastructure, providing some halo effect. However, cement purchasing decisions involve product-specific considerations where independent cement brand recognition matters significantly.

Building brand recognition requires sustained investment across multiple dimensions. Technical support teams providing application guidance and problem-solving for construction professionals build relationships driving specification decisions. Quality consistency over time establishes reputation reliability. Marketing investments including trade advertising, professional associations, and industry event participation gradually build awareness.

IPO Structure and Valuation Framework

Expected Issue Size and Offering Components

While formal IPO details await regulatory filings expected in September-October 2025, market intelligence and industry precedent suggest probable structures guiding investor assessment. Analysts project total issue size between ₹3,000-4,000 crore, positioning this among larger cement sector IPOs in recent years.

The structure will likely combine fresh equity issuance by JSW Cement with an offer-for-sale component by parent company JSW Group. Fresh equity proceeds fund expansion projects, debt reduction, and working capital requirements as outlined in strategic objectives. The OFS component allows parent company partial monetization of its investment while maintaining controlling stake, providing liquidity without diluting expansion capital available to the company.

Promoter shareholding post-IPO will likely settle around 65-70% of total equity. This ownership structure ensures continued family control and alignment while meeting regulatory requirements for minimum public float of 25%. The substantial retained promoter stake signals long-term commitment while providing adequate free float for institutional and retail investor participation.

The IPO will include reserved categories for retail individual investors, non-institutional investors, and qualified institutional buyers. Retail allocation typically comprises 35% of the public offering portion, with institutional categories receiving the balance based on demand dynamics during the subscription period.

Valuation Methodology and Peer Comparisons

Cement company valuations typically employ Enterprise Value-to-EBITDA multiples as primary methodology. This metric captures both market capitalization and net debt, normalizing for varying leverage levels across companies. EV/EBITDA enables comparison across manufacturers with different capital structures and debt management approaches.

Industry analysts project JSW Cement’s listing valuation multiples between 10-12x EV/EBITDA based on FY2025 or FY2026 earnings projections. This range reflects several offsetting factors supporting premiums or requiring discounts relative to established manufacturer valuations.

Positive valuation factors include modern manufacturing facilities incorporating contemporary technology enabling competitive operating costs per tonne. Newer plants benefit from superior energy efficiency, lower maintenance costs, and environmental compliance built into initial design. Southern India sourcing advantages, particularly limestone reserve quality and proximity to coastal coal import facilities, provide structural cost benefits.

The company’s growth trajectory with planned capacity additions offers volume expansion potential that mature manufacturers cannot match. For growth-oriented investors prioritizing revenue expansion over current profitability, this capacity increase narrative justifies premium valuations despite current scale limitations and market position gaps.

However, several factors constrain valuation premiums relative to industry leaders. JSW’s current operating EBITDA margins range 15-18%, lagging behind industry leaders achieving 20-25% margins through superior scale economics, brand premium pricing, and operational efficiency accumulated over decades. While newer plants should improve margins as utilization rates increase, near-term profitability lags peer benchmarks.

Limited distribution reach and brand recognition outside core markets create execution risk around volume growth assumptions underlying expansion plans. Achieving targeted capacity utilization requires successfully penetrating new markets against entrenched competitors with established dealer relationships and brand loyalty. This execution uncertainty warrants valuation discounts.

Price Band Expectations and Retail Participation

The IPO price band, typically announced approximately two weeks before subscription window opening, will likely position shares at ₹350-450 based on implied market capitalization and outstanding share count post-offering. Pricing aims to balance institutional investor demand, which favors conservative entry valuations providing upside potential, against promoter monetization expectations and company capital raising requirements.

Retail investor allocation dynamics significantly influence overall issue success and first-day listing performance. Retail participants often focus on short-term listing gains rather than long-term fundamental value, making subscription multiples and opening trading day performance critical for overall market perception.

Management roadshows scheduled for October 2025 across key financial centers including Mumbai, Bangalore, Delhi, and potentially international locations like Singapore and London will target institutional investors. These presentations highlighting operational progress, capacity expansion timelines, market positioning, and financial projections prove crucial in building order book demand and securing anchor investor commitments that signal institutional confidence.

Market Opportunities and Growth Catalysts

Southern India Infrastructure Development Surge

Southern states including Karnataka, Andhra Pradesh, Telangana, and Tamil Nadu are experiencing robust infrastructure development, urban expansion, and industrial investment. These regions demonstrate above-average GDP growth rates and construction activity levels compared to northern and eastern India.

Bangalore’s technology corridor continues expanding with office space construction, residential real estate development, and supporting infrastructure including roads, metro rail, and utilities. The city’s position as India’s technology capital drives sustained construction demand across commercial, residential, and infrastructure categories.

Hyderabad’s pharmaceutical manufacturing clusters and information technology hubs similarly generate construction activity. The city has emerged as a major destination for pharmaceutical research and manufacturing, requiring extensive industrial facility construction. Growing technology sector presence drives office space demand and residential real estate development.

Chennai’s automotive manufacturing base anchors industrial construction demand. The city serves as headquarters or major manufacturing location for multiple domestic and international automotive companies. Automotive sector expansion, including electric vehicle manufacturing investments, will drive factory construction and supporting infrastructure development.

Government infrastructure programs including national highway expansion, dedicated freight corridors, metro rail projects in multiple southern cities, and smart city initiatives consume substantial cement volumes. JSW’s manufacturing presence across southern states positions it favorably to capture this demand without incurring freight penalties affecting suppliers shipping from distant regions.

Premium and Specialty Product Segments

The Indian cement market increasingly differentiates between commodity-grade products and premium specialty cements commanding price premiums. This market segmentation creates margin enhancement opportunities for manufacturers with production flexibility and technical capabilities.

Portland Pozzolana Cement incorporating pozzolanic materials offers enhanced durability and reduced environmental impact. PPC products serve applications requiring long-term performance reliability including bridges, marine structures, and high-rise construction. Premium positioning enables pricing 5-10% above commodity OPC products.

Portland Slag Cement incorporating blast furnace slag provides superior resistance to sulfate attack and chloride penetration. PSC products suit coastal construction applications and underground structures exposed to aggressive environmental conditions. Technical performance advantages justify premium pricing for specialized applications.

Rapid-setting and ultra-high-strength cement formulations serve niche applications including precast concrete manufacturing, urgent repair work, and specialized construction techniques. These specialty products command significant premiums over commodity cement, often 15-25% price advantages, while serving smaller volume markets.

JSW has invested in manufacturing flexibility enabling production across product categories based on demand patterns. This capability allows capturing higher-margin specialty volumes rather than competing purely on commodity pricing where scale advantages decisively favor larger players like UltraTech.

Synergies Within JSW Group Ecosystem

JSW Cement benefits from operational and strategic synergies across the broader JSW Group conglomerate. These advantages, while difficult to precisely quantify, contribute meaningful cost efficiencies and strategic capabilities unavailable to standalone cement operators.

The group’s steel manufacturing operations provide indirect benefits through shared vendor relationships for coal procurement, freight logistics management, and energy sourcing. Established supplier relationships and procurement scale enable favorable pricing and reliable supply across group companies.

JSW Energy, the group’s power generation division, potentially supplies electricity at competitive rates to cement manufacturing facilities. Captive or preferential power access reduces exposure to grid tariff volatility while ensuring reliable supply for energy-intensive cement production. Power costs typically comprise 15-20% of manufacturing expenses, making even modest cost advantages significant at scale.

Shared corporate services across finance, human resources, information technology, legal, and strategic planning functions generate cost efficiencies versus standalone operators requiring dedicated functional teams. Group-level expertise in project execution, regulatory navigation, and stakeholder management accelerates cement division development.

Industry Challenges and Risk Factors

Overcapacity Concerns and Pricing Pressure

The Indian cement industry faces emerging overcapacity concerns as multiple manufacturers simultaneously expand production. Industry-wide capacity additions of approximately 40-50 MTPA are scheduled for commissioning during 2025-2027. This supply expansion occurs against demand growth projections of 5-6% annually, down from approximately 8% compound annual growth experienced during 2020-2024.

This supply-demand imbalance creates pricing pressure dynamics that disproportionately harm higher-cost producers or manufacturers with weaker distribution networks. Companies unable to secure adequate volume at prevailing market prices face difficult strategic choices between accepting low capacity utilization with poor fixed cost absorption or pursuing volume through aggressive pricing that erodes margins.

Overcapacity conditions typically compress industry-wide profitability as manufacturers compete for market share. Price wars, while temporarily benefiting buyers, destroy shareholder value and discourage necessary capital investment in capacity maintenance and technology upgrades. Smaller or financially weaker players may face viability challenges during extended periods of pricing pressure.

JSW’s expansion into this environment requires confidence that its cost position and market access will enable competitive capacity utilization rates despite industry-wide supply pressures. This assumption carries meaningful execution risk, particularly in new markets where JSW lacks established distribution presence and faces entrenched competitors with decades of market development.

Energy Cost Volatility and Input Price Risk

Coal and power together comprise 40-50% of cement manufacturing costs, making energy expense management absolutely critical for sustained profitability. Global coal prices experienced extreme volatility during 2022-2024, fluctuating from approximately $80 per tonne to peaks exceeding $400 before settling around $120-140 in early 2025.

This dramatic volatility creates earnings uncertainty for manufacturers unable to immediately pass through cost increases to customers. In competitive markets with excess capacity, price increases lag behind cost inflation by several months, compressing margins during cost spike periods. Companies lacking long-term fuel supply contracts or hedging mechanisms face maximum exposure to spot price volatility.

Freight costs for coal transportation from mines or ports to manufacturing facilities add further expense uncertainty. Indian Railways periodically adjusts freight tariffs, directly impacting delivered fuel costs. Truck rental rates for last-mile transportation fluctuate with diesel prices and freight market capacity utilization. Port handling costs for imported coal similarly vary, affecting overall fuel economics.

Power tariff increases by state electricity boards impact manufacturers reliant on grid electricity rather than captive generation. While captive power generation mitigates this exposure, it requires substantial upfront capital investment and operational expertise in power plant management. Many cement manufacturers increasingly invest in renewable energy including solar and wind to reduce fossil fuel dependence and cost volatility.

Regulatory and Environmental Compliance Requirements

Cement manufacturing faces increasingly stringent environmental regulations addressing air emissions, water consumption, solid waste management, and carbon intensity. Compliance requires ongoing investment in pollution control equipment, continuous emissions monitoring systems, and process modifications to reduce environmental impact.

Air quality regulations limit particulate matter, sulfur dioxide, and nitrogen oxide emissions from kilns and clinker production. Meeting these standards requires installation of electrostatic precipitators, bag houses, and selective catalytic reduction systems. Retrofit installations at existing facilities prove technically challenging and expensive, while new plants incorporate environmental controls from initial design.

Water availability represents an emerging constraint in water-stressed regions across India. Cement plants require substantial water volumes for cooling systems, dust suppression, and ancillary processes. Securing reliable water sources and obtaining regulatory approvals for water extraction adds complexity to greenfield site selection and facility development.

Mining lease acquisitions and renewals face complex approval processes involving multiple authorities at state and national levels. Environmental clearances for limestone quarries have become particularly challenging, with extended approval timelines and strict operating conditions including limits on blast timing, dust control requirements, and post-mining land reclamation obligations.

Carbon emissions reduction represents an emerging long-term challenge. Cement manufacturing inherently generates carbon dioxide through both fuel combustion and chemical decomposition of limestone. Industry decarbonization will require adoption of alternative fuels, carbon capture technologies, and potentially fundamental changes to cement chemistry. These transitions require significant capital investment and technological development.

Competitive Response from Established Players

Established cement manufacturers possess multiple defensive tools to protect market positions against emerging challengers. Price competition represents the most direct response, with larger players leveraging superior cost positions to strategically underprice new entrants in contested markets.

UltraTech, Adani, and other industry leaders can tactically compress prices in specific regions where JSW enters, accepting short-term margin pressure to prevent the newcomer from gaining distribution foothold and dealer relationships. This defensive pricing, while economically painful for incumbents, proves potentially devastating for challengers operating with thinner margins and less capital reserves to sustain losses during market entry phases.

Beyond pure pricing actions, incumbents can intensify distribution support through enhanced dealer credit terms, volume discounts, and exclusive supply arrangements that economically lock dealers into existing relationships. They can accelerate brand marketing and technical support investments in threatened regions, raising the customer acquisition cost JSW must bear to achieve brand awareness and contractor acceptance.

Larger players also possess acquisition capacity to purchase regional competitors, further consolidating market positions and limiting JSW’s potential growth pathways. If established manufacturers perceive JSW as a meaningful emerging threat, they could deliberately accelerate industry consolidation to pre-empt JSW’s expansion plans and maintain oligopolistic market structure.

Financial Metrics for Investment Evaluation

Operating Margin Analysis and Cost Structure

JSW Cement currently generates EBITDA operating margins in the 15-18% range according to market intelligence, below the 20-25% margins achieved by efficient established players including Shree Cement and UltraTech. This profitability gap reflects multiple factors including newer plants operating below optimal capacity utilization, distribution development costs for market penetration, and limited brand pricing power in competitive markets.

As capacity utilization improves through demand growth and successful market penetration, fixed cost absorption should strengthen, expanding margins toward peer levels. Manufacturing overhead, depreciation per tonne produced, and administrative costs all decline on a per-unit basis as production volumes increase across existing assets.

Variable cost management across raw materials, fuel, power, freight, and packaging determines competitiveness versus established manufacturers. JSW’s modern plants incorporating contemporary technology should achieve competitive variable costs, but this theoretical advantage requires validation through sustained operational performance demonstrating consistent achievement of target cost structures.

Return on Capital Employed and Equity Returns

Return on Capital Employed and Return on Equity measure how effectively management deploys invested capital to generate profits. These ratios provide insight into capital allocation discipline, operational efficiency, and sustainable profitability levels. Cement manufacturers with superior market positions, cost leadership, and pricing power typically achieve ROCE exceeding 15% and ROE above 18% on sustained basis.

JSW’s current return ratios likely lag these benchmarks, reflecting expansion-phase dynamics where capital deployment substantially precedes full earnings contribution from new assets. Aggressive capacity additions planned through 2025-2027 will further depress return ratios in the near term before improving as new plants ramp production and approach nameplate capacity utilization.

Investors evaluating JSW should focus on management’s projected return ratio trajectory over time. Critical questions include: when do new plants achieve cash flow breakeven, reach target capacity utilization levels, and generate returns exceeding the company’s weighted average cost of capital? Realistic, conservative assumptions on these metrics determine whether expansion creates or destroys shareholder value.

Leverage Metrics and Financial Flexibility

Debt service coverage ratio, calculated as EBITDA divided by debt service obligations including both principal and interest, indicates capacity to meet debt obligations from operating cash flow. Comfortable DSCR levels exceed 2.0x, providing cushion for cyclical industry downturns or unexpected cost pressures that temporarily compress profitability.

Post-IPO, JSW management targets reducing net debt-to-EBITDA ratio below 2.5x from current estimated levels around 3.5-4.0x. This improvement would align leverage with conservative industry practices while preserving debt capacity for future growth investments without triggering credit rating concerns.

Interest coverage ratio, measured as EBITDA divided by interest expense, similarly reveals financial health and debt servicing ease. Ratios comfortably above 4.0x indicate strong debt service capacity, while readings below 2.5x suggest financial stress requiring urgent deleveraging through either accelerated debt repayment or equity capital infusion.

Cash Generation and Working Capital Efficiency

Cement manufacturers typically demonstrate strong cash conversion characteristics, with operating cash flow closely tracking EBITDA after accounting for modest working capital requirements. Receivables collection, inventory management, and supplier payment terms optimization all influence cash generation and liquidity.

JSW’s working capital requirements should remain modest relative to revenues, typical for cement operations with relatively short operating cycles. However, aggressive distribution network expansion requires extended trade credit to attract new dealers and incentivize inventory carrying, temporarily increasing receivables and pressuring cash conversion. Monitoring days sales outstanding trends reveals management discipline in balancing growth ambitions against cash flow sustainability.

Free cash flow generation after accounting for maintenance capital expenditure determines dividend paying capacity and financial flexibility for opportunistic investments. During JSW’s aggressive expansion phase, free cash flow will remain pressured as growth capital expenditure substantially exceeds depreciation. As expansion moderates in outer years, improving free cash flow generation should support enhanced shareholder returns.

Investment Considerations by Investor Profile

Growth-Oriented Long-Term Investors

Investors seeking exposure to India’s infrastructure development and urbanization themes with tolerance for execution risk may find JSW Cement compelling. The company offers volume expansion potential substantially exceeding mature manufacturers, with capacity potentially increasing 50% or more over 2025-2030 through planned organic development.

This growth profile suits investors willing to accept near-term earnings volatility and modest current profitability while expansion progresses, with expectations of improved returns as new plants commission and mature operationally. A 5-7 year investment horizon enables riding through construction and commissioning phases to capture value creation as operational scale approaches peer levels.

Long-term investors should verify management’s track record executing complex industrial projects within budget and scheduled timelines. JSW Group’s steel division provides some confidence through demonstrated manufacturing competence in capital-intensive industries. However, cement operations involve distinct distribution challenges and market penetration requirements that steel industry experience doesn’t fully address.

Value Investors Seeking Entry Valuation

Value-focused investors prioritizing attractive entry valuations providing downside protection if growth falls short of projections require careful assessment whether projected 10-12x EV/EBITDA pricing offers sufficient discount to intrinsic value given execution risks and competitive uncertainties.

Comparing JSW’s expected valuation against established manufacturers helps gauge relative attractiveness. If UltraTech trades at 14-15x EV/EBITDA despite mature growth profile and industry-leading scale, JSW’s discount appears modest given its substantial scale disadvantages and unproven distribution capabilities. Conversely, if slower-growing regional players trade at 8-9x multiples, JSW’s premium may be justified by superior growth potential and modern asset base.

Value investors should model downside scenarios where capacity utilization disappoints due to industry overcapacity or distribution challenges, operating margins compress under sustained competitive pricing pressure, or expansion requires more capital than initially budgeted due to construction delays or cost overruns. If these stress cases still offer acceptable returns from entry valuation, sufficient margin of safety may exist to justify investment.

Short-Term Listing Gains Focus

Short-term traders focused on first-week listing gains evaluate factors distinct from long-term fundamental analysis. Key considerations include expected subscription multiples, gray market premium indications, anchor investor allocation quality, and overall equity market sentiment during the listing period.

Strong subscription demand, particularly from qualified institutional buyers, typically predicts positive listing day performance. Anchor allocation to marquee domestic mutual funds or prominent foreign institutional investors signals professional investor confidence potentially supporting early trading prices.

However, listing performance depends heavily on broader market conditions prevailing during the listing day, with strong negative correlation during market corrections regardless of individual issue quality. Even fundamentally sound IPOs can list below issue price during adverse market environments characterized by risk-off sentiment or liquidity constraints.

Frequently Asked Questions (FAQs)

When is the JSW Cement IPO expected to launch?

The JSW Cement initial public offering is projected for the fourth quarter of 2025, likely during October or November. The formal timeline depends on regulatory clearances from the Securities and Exchange Board of India. Market participants expect the draft red herring prospectus filing in September 2025, followed by 30-45 days for regulatory review and approval.

Management roadshows targeting institutional investors would commence in October, with the subscription window opening in late October or November 2025. Some analysts speculate the launch could extend into early Q1 2026 (January-February) if regulatory processes require additional time or if management determines market conditions warrant brief delay. The exact schedule will be announced publicly following SEBI approval of the offering documents.

What is JSW Cement’s current production capacity compared to industry leaders?

JSW Cement currently operates approximately 40 million tonnes per annum of installed cement manufacturing capacity. This is distributed across facilities in Karnataka, Maharashtra, Odisha, and Andhra Pradesh. The capacity positions JSW as a mid-sized national player.

By comparison, UltraTech Cement operates approximately 140 MTPA, Adani Cement has around 78 MTPA, Shree Cement controls roughly 47 MTPA, and Dalmia Cement operates

approximately 35 MTPA. JSW’s current capacity represents approximately 8-9% of India’s total cement capacity estimated at 450-470 MTPA. The company has announced expansion plans targeting capacity increases to 55-60 MTPA by 2027, which would strengthen its market position while still maintaining a substantial scale gap versus top-tier players.

Why did Managing Director Parth Jindal make candid remarks about JSW’s competitive position?

Parth Jindal’s unusually frank assessment acknowledging that JSW currently lacks the capacity to directly challenge industry giants like Adani and Birla serves multiple strategic communication purposes. This transparency establishes realistic investor expectations, reducing risk of valuation inflation based on overly optimistic growth projections or market disruption scenarios that may prove unsustainable.

The commentary signals management’s commitment to measured organic growth rather than aggressive acquisition-driven expansion that might involve overpaying for assets. This approach reflects lessons from companies that expanded too rapidly through mergers and acquisitions, often inheriting operational inefficiencies and overvalued assets.

The transparent communication style also reflects generational shifts in corporate messaging, with younger executives demonstrating greater comfort with authentic, direct language over traditional polished corporate communications.

How will JSW Cement deploy the IPO proceeds?

IPO proceeds will be allocated across three primary objectives over a 24-36 month deployment period following listing. Approximately 60-65% is expected to fund expansion capital including greenfield plant construction, clinker production unit development, limestone mining lease acquisitions, and logistics infrastructure including rail connectivity and regional grinding units.

An estimated 25-30% of proceeds will support debt reduction, retiring high-cost debt accumulated during initial expansion phases. This deleveraging aims to reduce net debt-to-EBITDA ratio from current estimated levels around 3.5-4.0x to below 2.5x, improving credit metrics and financial flexibility.

The remaining 5-10% will address working capital requirements supporting distribution network expansion and maintaining financial flexibility for strategic opportunities. The exact allocation will be detailed in the official IPO prospectus, with management retaining flexibility to adjust based on market conditions.

What valuation multiples are expected for JSW Cement at listing?

Industry analysts project JSW Cement will list at valuation multiples between 10-12x enterprise value-to-EBITDA based on FY2026 earnings projections. This range reflects offsetting factors including positive elements like modern manufacturing technology enabling competitive costs, southern India sourcing advantages, growth trajectory through capacity additions, and JSW Group operational synergies.

Factors constraining higher valuations include current operating margins of 15-18% versus 20-25% for industry leaders, limited distribution network reach outside core markets, near-term earnings dilution from aggressive expansion, and execution risk around achieving projected growth targets.

For context, established manufacturers trade at varied multiples with UltraTech at approximately 14-15x, Shree Cement at 12-13x, and smaller regional players at 8-10x. JSW’s expected valuation positions it as a growth-oriented mid-tier player without commanding the premium of market leaders or deep discount of pure regional operators.

What are the primary risks facing JSW Cement that investors should evaluate?

Multiple significant risks warrant careful consideration. Industry overcapacity represents a primary concern, with 40-50 MTPA of new capacity scheduled for commissioning industry-wide during 2025-2027 against demand growth of only 5-6% annually. This supply-demand imbalance creates pricing pressure and capacity utilization challenges, particularly for newer entrants without established distribution networks.

Execution risk surrounding successful plant commissioning on schedule and budget while simultaneously developing distribution networks in competitive new markets requires complex operational coordination.

Energy cost volatility including coal price fluctuations and power tariff increases could compress margins before market position enables pricing power to offset input cost inflation. Competitive response from well-capitalized incumbents who can deploy aggressive pricing, enhanced dealer support, or strategic acquisitions to limit JSW’s growth pathways represents another material risk.

Regulatory challenges including mining clearance delays, environmental compliance requirements, and water availability constraints could slow expansion or increase capital requirements beyond initial projections. Finally, macroeconomic demand slowdown due to weaker infrastructure spending, real estate sector challenges, or broader economic headwinds would undermine volume assumptions underlying the expansion strategy.

Should retail investors participate in the JSW Cement IPO?

Retail investor participation appropriateness depends on individual risk tolerance, investment timeframe, and portfolio objectives. Investors may consider participating if they maintain a 5+ year investment horizon, believe in India’s long-term infrastructure growth story, accept near-term earnings volatility during expansion phases, and find the expected 10-12x EV/EBITDA valuation attractive for a high-growth mid-tier cement manufacturer.

Retail investors should consider avoiding the offering if they seek stable dividend income, require near-term profitability, are uncomfortable with execution risks inherent in aggressive capacity expansion, or prefer established manufacturers with proven market positions and consistent profitability. Cement represents a cyclical, capital-intensive, commodity-like industry.

While offering infrastructure sector exposure, it lacks the growth potential of technology or consumer sectors. Position sizing should reflect these characteristics, with cement holdings comprising modest allocation within a broader diversified portfolio.

How does JSW Cement differentiate itself from other cement manufacturers?

JSW Cement distinguishes itself through several factors compared to both established players and recent market entrants. Corporate parentage within the diversified JSW Group provides financial strength, operational expertise in capital-intensive manufacturing, and synergies around coal procurement and logistics unavailable to standalone operators. This backing reduces financial distress risk while enabling capital access for expansion.

Geographic focus concentrated in southern and western high-growth regions offers structural demand advantages versus pan-India players serving slower-growth markets. Modern asset base with recently commissioned plants incorporating latest technology delivers superior energy efficiency and lower maintenance costs compared to companies operating aging facilities requiring costly retrofits.

Transparent leadership communication style under Managing Director Parth Jindal contrasts with typical corporate messaging, potentially building investor trust through realistic expectation-setting rather than overpromising.

The explicit preference for organic growth over acquisition-driven expansion differentiates from competitors pursuing rapid consolidation strategies that carry integration risks and potential overpayment concerns. However, JSW also faces unique challenges including limited operating history in cement (only six years), unproven distribution development capabilities outside core markets, and the need to execute aggressive expansion while maintaining profitability targets.

What market developments should investors monitor regarding JSW Cement?

Several critical indicators will reveal execution progress and competitive positioning evolution. Quarterly capacity utilization rates across existing and newly commissioned plants will demonstrate market acceptance and distribution network effectiveness. Utilization rates consistently above 70-75% would indicate successful market penetration, while sustained low utilization suggests distribution or competitive challenges.

Operating margin trajectory will reveal cost management effectiveness and pricing power development. Sequential margin improvement toward the 20%+ levels achieved by efficient manufacturers would validate the investment thesis, while sustained margin compression would raise concerns about competitive positioning.

Market share trends in key southern and western state markets will show whether JSW gains share from incumbents or struggles to penetrate established distribution networks.

Debt metrics including net debt-to-EBITDA ratio and interest coverage will indicate financial health and deleveraging progress post-IPO. Announced capacity expansion project timelines and commissioning updates will demonstrate execution capabilities on complex industrial projects. Commentary from established competitors including UltraTech, Adani Cement, and Shree Cement regarding industry capacity utilization, pricing environment, and competitive dynamics will provide context for assessing JSW’s operating environment and strategic challenges.

Conclusion and Investment Outlook

JSW Cement’s anticipated initial public offering represents a significant milestone in the company’s evolution from regional manufacturer toward national market presence. Managing Director Parth Jindal’s candid acknowledgment of current competitive limitations establishes realistic foundations for investor evaluation, contrasting notably with typical corporate optimism characteristic of pre-IPO positioning.

The investment proposition centers on a compelling growth narrative built on planned capacity expansion, modern manufacturing technology incorporating superior energy efficiency, geographic positioning in high-growth southern markets, and JSW Group synergies across procurement and logistics. For investors seeking infrastructure sector exposure through a growth-oriented mid-tier manufacturer, JSW merits serious consideration within appropriate portfolio allocation frameworks.

However, the opportunity carries substantial execution risks that cannot be dismissed or minimized. Successfully commissioning multiple plants according to schedule and budget, developing competitive distribution networks in contested markets, managing through industry overcapacity conditions, and achieving targeted profitability all require sustained operational excellence over multi-year timeframes. Industry experience demonstrates that even well-capitalized, experienced manufacturers encounter expansion challenges including cost overruns, commissioning delays, and market penetration difficulties.

JSW’s expected valuation at 10-12x EV/EBITDA multiples offers modest discount to established industry leaders despite meaningful gaps in scale, market position, and profitability. Whether this pricing provides adequate risk compensation depends substantially on investor confidence in management’s ability to deliver growth targets without sacrificing margins or assuming imprudent financial leverage.

The cement sector fundamentally benefits from India’s long-term infrastructure development, urbanization trends, and construction demand growth. Urban expansion, highway networks, metro rail systems, industrial parks, and housing requirements will drive cement consumption for decades, creating market space for multiple successful manufacturers. JSW’s challenge involves capturing meaningful share of this demand against entrenched competitors possessing superior resources and established market positions.

As the IPO progresses through regulatory approval processes during autumn 2025, prospective investors should carefully evaluate subscription demand intensity, anchor investor participation quality, management roadshow messaging consistency, and competitive developments that might intensify or moderate the industry operating environment JSW will navigate.

For long-term investors with appropriate risk tolerance, JSW may present compelling growth opportunity provided management delivers on capacity expansion commitments, successfully penetrates new markets, and achieves competitive cost positions. For conservative investors prioritizing proven profitability and market leadership, established manufacturers may offer superior risk-adjusted returns despite lower growth trajectories.

About the Author

Financial Markets Research Team of Nueplanet

Our content development team comprises experienced analysts specializing in Indian capital markets, initial public offerings, and industrial sector research. We are committed to delivering accurate, balanced, thoroughly researched financial content based exclusively on verified information from official regulatory filings, company disclosures, and authoritative market sources.

Our Commitment to Accuracy and Transparency:

- All financial data sourced from official company announcements, SEBI filings, stock exchange disclosures, and regulatory documents

- Market intelligence verified through multiple authoritative sources including industry associations and government publications

- Analysis grounded in publicly available information without speculation or unverified claims

- Regular content updates reflecting latest developments and official announcements

- Clear distinction between factual reporting and analytical interpretation

Professional Standards:

We adhere to highest standards of financial journalism and content creation. Our analyses aim to inform investor decision-making through comprehensive, objective examination of investment opportunities, risks, competitive dynamics, and market context. We do not provide personalized investment advice or recommendations to buy, sell, or hold specific securities.

Transparency Statement:

This content is provided for informational and educational purposes exclusively. It does not constitute investment advice, financial planning guidance, or solicitation to purchase securities. The research team may or may not hold positions in securities mentioned in this analysis.

Published: August 05, 2025

Last Updated: August 05, 2025

Disclaimer: This article serves informational and educational purposes only. It does not constitute financial advice, investment recommendation, or solicitation to purchase securities. Prospective investors must conduct independent research, review official IPO prospectus documents, and consult with qualified financial advisors before making investment decisions. Initial public offerings carry inherent risks including potential loss of capital, price volatility, and uncertainty regarding future performance.

Past performance of similar offerings or existing companies does not guarantee future results. All data and information provided is believed accurate based on sources available at publication time, but no warranty is made regarding completeness or accuracy. Investors should recognize that cement manufacturing represents a cyclical, capital-intensive industry subject to commodity price volatility, regulatory changes, and competitive dynamics that may materially impact financial performance.

Related Content Suggestions:

- Comparative analysis of recent cement sector IPOs including performance tracking

- Deep dive into Indian infrastructure spending trends and cement demand correlation

- Guide to evaluating manufacturing company financials and operational metrics

- Regional cement market dynamics across southern India states

- Environmental regulations impact on cement manufacturing sector

Helpful Resources

Latest Posts

IND vs ENG Highlights – Oval Finale & Series For India (Draw 2–2)

India’s Next Test Series: WTC 2025–27 Roadmap, Upcoming Matches & Captains to Watch

Comprehensive Guide to MCC and NEET‑UG Counselling 2025 at mcc.nic.in

Mohammed Siraj Shines as India Levels Anderson‑Tendulkar Trophy 2025

KSRTC Bus Strike in Karnataka: Cause, Impact & Ongoing Protests Explained

Post Comment