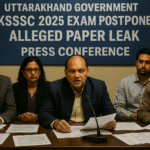

CG Power Share Price: Market in Focus

CG Power share price has been in focus after the company’s major OSAT facility plans and market movements. This blog explains the latest updates, stock performance, and investor outlook.

Table of Contents

Published: August 29, 2025 | Last Updated: August 29, 2025

Overview

CG Power and Industrial Solutions Limited has attracted significant attention from market participants following its announcement regarding semiconductor manufacturing infrastructure. The company, which operates under the Murugappa Group, has outlined plans for establishing an Outsourced Semiconductor Assembly and Test facility in India. This development aligns with national initiatives focused on reducing dependence on imported semiconductor products and building domestic manufacturing capabilities.

The stock has experienced notable trading activity on both the National Stock Exchange and Bombay Stock Exchange platforms. Market observers are analyzing the potential implications of this strategic shift for the company’s business model and revenue composition. Understanding the financial metrics, execution timeline, and market dynamics surrounding this development requires examination of multiple factors including regulatory frameworks, capital expenditure requirements, and industry trends.

This analysis examines the company’s recent announcements, market performance data, financial position, and the broader context of India’s semiconductor industry development. The information presented is based on publicly available data from stock exchanges, regulatory filings, and official government sources.

Recent Corporate Announcement Details

Semiconductor Facility Initiative

On December 15, 2024, CG Power announced its intention to establish a semiconductor assembly and testing facility. According to the company’s official statement, the project involves establishing infrastructure in Tamil Nadu with an estimated capital requirement of Rs 3,500 crores. The announcement was made through formal channels in Chennai, with company leadership outlining the strategic rationale for entering the semiconductor manufacturing sector.

The facility is designed to address assembly and testing operations for semiconductor products. These operations represent specific stages in the semiconductor manufacturing value chain, distinct from wafer fabrication processes. The company stated that the facility would create approximately 5,000 direct employment positions upon completion and full operationalization.

Chairman Vellayan Subbiah’s statement emphasized the project’s alignment with national objectives for semiconductor manufacturing capabilities. The announcement highlighted potential benefits including employment generation, technology transfer opportunities, and contribution to reducing import requirements for semiconductor products.

Market Response and Trading Activity

According to data from the National Stock Exchange, CG Power shares opened at Rs 485 on December 16, 2024, compared to the previous closing price of Rs 430. This represented an opening premium of approximately 12.8%. Trading volumes on that date reached 45 million shares, significantly higher than the average daily volume recorded in preceding weeks.

The stock reached an intraday high of Rs 512 during trading hours on December 16, 2024, before closing at Rs 498. This closing price represented a single-day gain of 15.8% compared to the previous session. The Nifty 50 index recorded a gain of 0.7% on the same trading day, providing context for the stock’s relative performance.

Trading data indicates increased participation from both institutional and retail investor categories. The elevated volumes suggest heightened interest in the stock following the semiconductor facility announcement. Market participants monitored the stock’s price movement relative to broader market indices and sectoral peers.

Government Recognition

Union Minister Ashwini Vaishnaw, who heads the Ministry of Electronics and Information Technology, acknowledged the company’s announcement through official channels. The minister’s statement described the project as significant for India’s semiconductor manufacturing ecosystem. This governmental recognition reflects the project’s alignment with national policy priorities under the India Semiconductor Mission framework.

The India Semiconductor Mission operates under the Ministry of Electronics and Information Technology and coordinates semiconductor industry development initiatives. The mission administers incentive schemes and provides policy support for semiconductor manufacturing projects. CG Power’s project falls within the categories of semiconductor infrastructure that the mission seeks to promote.

Strategic Context and Industry Background

India’s Semiconductor Industry Development

India currently imports substantial quantities of semiconductor products to meet requirements across electronics manufacturing, telecommunications, automotive, and industrial sectors. According to industry estimates, annual semiconductor imports approximate $65 billion, representing a significant component of the country’s technology product imports. This import dependence creates vulnerability to supply chain disruptions and price fluctuations in global semiconductor markets.

The government launched the India Semiconductor Mission in December 2021 with allocated funding of Rs 76,000 crores. The mission’s objectives include attracting semiconductor manufacturing investments, building domestic capabilities across the semiconductor value chain, and establishing India as a participant in global semiconductor supply networks. The mission offers financial incentives and policy support for approved semiconductor projects.

The Production Linked Incentive scheme for semiconductors provides capital expenditure support for qualifying projects. Projects approved under this scheme receive financial assistance calculated as a percentage of capital investment, subject to achieving specified production and investment milestones. The scheme aims to reduce the financial burden of establishing capital-intensive semiconductor manufacturing infrastructure.

OSAT Operations Explained

Outsourced Semiconductor Assembly and Test facilities perform specific functions in semiconductor manufacturing. After wafer fabrication is completed, individual chips must be separated, packaged, and tested before distribution to customers. OSAT facilities specialize in these post-fabrication processes, providing services to semiconductor design companies and integrated device manufacturers.

Assembly operations involve mounting semiconductor dies onto substrates, establishing electrical connections, and encapsulating the components in protective packaging. Testing operations verify that finished semiconductor products meet specified electrical and functional parameters. These processes require specialized equipment, controlled environments, and skilled technical personnel.

India currently has limited OSAT infrastructure, requiring companies to utilize facilities located in other countries including Malaysia, Singapore, Taiwan, and Vietnam. This necessitates shipping products internationally for assembly and testing, adding time and cost to the supply chain. Domestic OSAT capabilities would allow shorter supply chains for semiconductor products manufactured or consumed in India.

CG Power’s Existing Business Operations

CG Power and Industrial Solutions Limited has operated in electrical equipment manufacturing for multiple decades. The company produces transformers, switchgear, motors, and other electrical infrastructure products for power generation, transmission, and distribution applications. These products serve utility companies, industrial facilities, and infrastructure projects.

The company’s technical capabilities include electrical engineering design, manufacturing operations, quality control processes, and after-sales service networks. This industrial experience provides a foundation that may transfer to semiconductor manufacturing operations, particularly in areas like precision manufacturing, quality systems, and industrial customer relationships.

The Murugappa Group, which controls CG Power, operates businesses across multiple industrial sectors including engineering, financial services, and agricultural products. The group’s diversified operations and financial resources provide organizational support for large capital projects. This corporate backing reduces execution risks associated with entering capital-intensive industries like semiconductor manufacturing.

Financial Analysis and Investment Considerations

Capital Expenditure and Funding Structure

The announced semiconductor facility requires total capital expenditure of Rs 3,500 crores according to company statements. This investment will be deployed across three implementation phases spanning several years. The first phase allocation stands at Rs 1,200 crores for land acquisition, regulatory compliance, and infrastructure development. The second phase requires Rs 1,800 crores for equipment procurement and installation. The third phase involves Rs 500 crores for production ramp-up and working capital requirements.

Companies undertaking large capital projects typically utilize multiple funding sources including internal accruals, equity issuance, and debt financing. The specific funding structure for CG Power’s semiconductor project has not been disclosed in detail. Investors should monitor future announcements regarding equity dilution through rights issues or preferential allotments, as well as changes in the company’s debt levels.

Financial Position Assessment

According to financial statements for the quarter ending September 2024, CG Power reported a debt-to-equity ratio of 0.47. This metric indicates the company maintains moderate leverage compared to its equity base. The relatively low debt levels provide flexibility for additional borrowing to fund capital projects without exceeding prudent leverage thresholds.

Operational cash flow averaged Rs 285 crores across the three quarters reported in fiscal year 2024-25. Positive operational cash generation indicates the existing business produces cash that can partially fund new investments. However, the semiconductor project’s capital requirements substantially exceed quarterly operational cash flows, necessitating external funding sources.

The company’s interest coverage ratio of 8.3 times indicates that earnings before interest and taxes exceed interest expenses by a comfortable margin. This suggests the company can service additional debt obligations without financial stress. However, investors should note that new project debt increases absolute interest expense, affecting future coverage ratios until the project generates revenues.

Working capital management metrics show improvement, with inventory turnover increasing from 4.2 times to 5.1 times over the past year. Efficient working capital management frees up cash for other uses and indicates operational effectiveness. These metrics provide context for evaluating management’s ability to execute complex projects efficiently.

Valuation Metrics and Considerations

As of the December 16, 2024 closing price of Rs 498, CG Power shares traded at a price-to-earnings ratio of approximately 28.5 times based on trailing twelve-month earnings. This valuation multiple exceeds the average for Indian electrical equipment manufacturers, which typically trade at price-to-earnings ratios between 18-22 times earnings.

The valuation premium reflects market expectations regarding the semiconductor project’s potential contribution to future earnings. Investors are incorporating assumptions about successful project execution, revenue generation timelines, and profitability margins into their valuation assessments. However, these assumptions carry execution risks that could affect actual outcomes.

Valuation analysis becomes complex when companies announce entry into new business segments. Traditional valuation methods based on historical earnings may not fully capture the value of future projects. Conversely, optimistic projections about new ventures may not materialize as expected, leading to valuation adjustments. Investors should consider multiple valuation approaches and scenario analyses when evaluating such situations.

The stock’s trading volumes and price volatility have increased following the semiconductor announcement. Higher volatility creates both opportunities and risks for investors. Short-term traders may exploit price fluctuations, while long-term investors must tolerate increased price uncertainty while the project progresses through development stages.

Implementation Timeline and Execution Phases

Phase One: Infrastructure Development (Target: December 2025)

The initial implementation phase focuses on establishing the physical infrastructure required for semiconductor manufacturing operations. This includes acquiring suitable land in Tamil Nadu’s industrial zones, obtaining necessary environmental clearances, and constructing buildings to house manufacturing equipment and supporting facilities.

Land acquisition for industrial projects in India requires compliance with multiple regulations including land use approvals, environmental impact assessments, and local authority permissions. The timeline for completing these regulatory processes affects the overall project schedule. Delays in obtaining approvals can cascade through subsequent phases, extending the time to operational status.

Infrastructure development includes constructing cleanroom facilities that maintain controlled environments necessary for semiconductor operations. These specialized facilities require sophisticated HVAC systems, contamination control measures, and utility systems providing uninterrupted power and water supply. The technical complexity of cleanroom construction demands specialized contractors and extended construction timelines.

Phase Two: Equipment Installation and Technology Transfer (Target: June 2027)

The second phase involves procuring and installing semiconductor assembly and testing equipment. This equipment is manufactured by specialized suppliers, primarily located in Japan, the Netherlands, and the United States. Equipment procurement timelines depend on supplier delivery schedules, which can extend 12-18 months for complex semiconductor manufacturing tools.

Technology transfer arrangements with international partners form a critical component of Phase Two. These partnerships provide access to established manufacturing processes, quality control methodologies, and technical expertise. The company has indicated preliminary discussions with firms from South Korea and Japan, though specific partnership agreements have not been publicly disclosed.

Workforce recruitment and training programs must parallel equipment installation to ensure adequate personnel are available when operations commence. Semiconductor manufacturing requires engineers and technicians with specialized skills in areas like process control, quality assurance, and equipment maintenance. Developing this workforce may require collaboration with technical institutes and training programs.

Phase Three: Production Ramp-Up (Target: Full Capacity by March 2029)

The final implementation phase involves progressively increasing production volumes from initial trial runs to full capacity utilization. Semiconductor manufacturing facilities typically achieve full production capacity gradually as processes are optimized and product yields improve. The company projects 75% capacity utilization by December 2027 and full capacity by March 2029.

Production ramp-up requires customer qualification processes where potential customers evaluate the facility’s capabilities and approve it for manufacturing their products. This qualification process involves producing sample lots, conducting quality audits, and demonstrating consistent performance over time. Customer qualification timelines vary but typically require several months to complete.

Revenue generation commences during the ramp-up phase, though initial revenues may not cover full operational costs until production reaches higher capacity levels. The project’s financial viability depends on achieving projected capacity utilization levels and securing adequate customer orders to sustain production volumes.

Risk Factors and Challenges

Technology and Execution Risks

Establishing semiconductor manufacturing capabilities involves significant technological complexity. The company must successfully transfer technology from international partners, integrate complex equipment systems, and achieve acceptable production yields. Each of these elements carries execution risk that could delay timelines or increase costs beyond initial projections.

Manufacturing yield rates determine the percentage of products that meet quality specifications. Low yields increase per-unit costs and reduce profitability. New semiconductor facilities typically experience lower yields initially, with improvement occurring as processes are optimized. The time required to achieve target yield levels affects the project’s financial performance trajectory.

Equipment integration challenges may arise when combining tools from multiple suppliers into coordinated production lines. Compatibility issues, software integration problems, or unexpected technical difficulties could extend commissioning timelines. The company’s limited prior experience in semiconductor manufacturing may increase the likelihood of encountering such challenges.

Regulatory and Policy Risks

Government policies significantly influence semiconductor project economics through incentive schemes, import duties, and regulatory frameworks. Changes in Production Linked Incentive scheme parameters, environmental regulations, or industrial licensing requirements could affect project costs or timelines. While current policies favor semiconductor manufacturing, policy environments can change with government priorities.

Environmental clearances for industrial facilities require compliance with pollution control standards, waste management protocols, and environmental impact assessments. Delays in obtaining clearances or requirements for additional environmental protection measures could increase costs or extend timelines. Ongoing compliance with environmental regulations adds operational complexity and cost.

Labor regulations, tax policies, and infrastructure availability in the facility’s location influence operational costs and efficiency. Changes in state or national policies affecting any of these factors could impact project economics. Investors should monitor policy developments that might affect semiconductor manufacturing operations.

Market and Competitive Risks

The global semiconductor industry experiences cyclical demand patterns influenced by electronics sales, inventory levels, and macroeconomic conditions. Semiconductor downturns reduce demand for assembly and testing services, affecting OSAT facility utilization rates and revenues. Projects initiated during favorable market conditions may face different demand environments when operations commence.

Established OSAT providers in Asia possess significant advantages including operational experience, established customer relationships, and economies of scale. CG Power will compete against these established players while simultaneously building capabilities and customer base. Competitive pricing pressure could affect profitability margins, particularly during the initial operational phases.

Customer concentration risk arises if the facility depends heavily on few large customers for revenue. Loss of a major customer or changes in customer requirements could significantly impact utilization rates. Diversifying the customer base requires time and marketing effort to establish relationships with multiple semiconductor companies.

Sector Impact and Broader Implications

Employment and Skill Development

The semiconductor facility’s projected 5,000 direct employment positions contribute to India’s technical workforce development objectives. These positions span multiple skill levels from engineering roles requiring advanced technical degrees to technician and operational positions. The facility’s training programs will develop specialized skills relevant to semiconductor manufacturing.

Indirect employment opportunities arise across the value chain including equipment maintenance services, materials supply, logistics, and supporting services. Industry estimates suggest semiconductor manufacturing generates approximately three indirect jobs for each direct position, potentially creating 15,000 additional employment opportunities in the surrounding region.

Collaboration with technical institutions and universities can address skill development needs while benefiting the broader education ecosystem. Industry-academia partnerships facilitate curriculum development, student internships, and research collaborations that enhance the quality of technical education. These partnerships contribute to developing a sustainable talent pipeline for the semiconductor industry.

Supply Chain Development

Domestic semiconductor assembly and testing capabilities reduce the need to ship products internationally for these processes. This supply chain simplification benefits Indian electronics manufacturers, automotive companies, and telecommunications equipment producers by reducing logistics costs and delivery times. Shorter supply chains also reduce vulnerability to international shipping disruptions.

The facility may attract related businesses including packaging materials suppliers, specialty chemicals manufacturers, and logistics service providers. This cluster effect can create a regional semiconductor ecosystem that provides efficiency benefits through proximity and specialization. Such clusters have historically driven regional economic development in other semiconductor manufacturing locations.

Import substitution for semiconductor assembly and testing services improves India’s trade balance in electronics and technology products. While the facility will still require imported equipment and materials, the value addition from domestic assembly and testing operations reduces net imports. This contributes to national objectives for trade balance improvement and currency stability.

Technology Development and Innovation

Establishing semiconductor manufacturing capabilities creates opportunities for indigenous technology development and innovation. As Indian engineers and researchers gain experience with semiconductor processes, they can contribute to process improvements, new product development, and adaptation of technologies to local requirements. This knowledge accumulation benefits the broader technology ecosystem.

Research and development activities associated with semiconductor manufacturing may generate intellectual property in areas like process optimization, packaging techniques, or testing methodologies. This intellectual property contributes to India’s technology assets and can be commercialized through licensing or application in related industries.

Collaboration between industry and research institutions on semiconductor-related projects enhances India’s research capabilities in materials science, electrical engineering, and related fields. Government support for semiconductor research through funding programs and infrastructure development complements private sector investments like CG Power’s facility.

Comparative Analysis with Industry Peers

Other Indian Semiconductor Initiatives

Several Indian companies have announced semiconductor manufacturing projects in recent years. Tata Electronics has outlined plans for semiconductor fabrication facilities in partnership with international technology providers. Vedanta Group announced semiconductor manufacturing investments, though these projects have encountered various implementation challenges. Each project targets different segments of the semiconductor value chain.

CG Power’s focus on OSAT operations differs from wafer fabrication projects in terms of capital intensity, technical complexity, and time to operationalization. OSAT facilities generally require lower capital investment than wafer fabrication plants, which can exceed $10 billion for advanced nodes. This capital efficiency may provide advantages in terms of financial risk and return on investment timelines.

The company’s established industrial operations and customer relationships differentiate it from new entrants to semiconductor manufacturing. Existing customers in power infrastructure and industrial sectors represent potential initial customers for power semiconductor devices and industrial control chips. This built-in market access reduces customer acquisition challenges faced by pure-play semiconductor startups.

Global OSAT Industry Context

Major global OSAT providers include companies like ASE Technology Holding, Amkor Technology, and JCET Group, primarily based in Taiwan, China, and South Korea. These companies possess decades of operational experience, extensive customer relationships, and technological expertise across multiple semiconductor packaging and testing technologies. They represent both benchmarks for operational performance and competitive threats.

India’s entry into OSAT operations occurs as semiconductor supply chains undergo geographic diversification. Geopolitical considerations, supply chain resilience objectives, and “China plus one” strategies by multinational companies create opportunities for new manufacturing locations. India’s large domestic market, engineering talent pool, and improving business environment position it as a potential alternative OSAT location.

The global OSAT market size approximates $40-45 billion annually, with growth driven by increasing semiconductor content in electronic devices, automotive electrification, and data center expansion. Market projections suggest continued growth in OSAT services as semiconductor demand increases. However, industry consolidation trends and technological requirements favor established players with scale and resources.

Investment Perspective and Considerations

Shareholder Value Implications

The semiconductor project represents a strategic transformation for CG Power, potentially altering the company’s business composition, growth trajectory, and risk profile. If successfully executed, the facility could contribute 35-40% of company revenues by 2030 according to management projections. This would represent a fundamental shift from the company’s current business mix.

Revenue diversification into semiconductor manufacturing reduces dependence on the electrical equipment sector, which is subject to infrastructure spending cycles and power sector investments. However, it also introduces exposure to semiconductor industry cycles and competitive dynamics. The net effect on shareholder value depends on relative profitability levels and growth rates between the two business segments.

The project’s capital intensity affects near-term financial metrics including return on equity and return on assets as invested capital increases before revenue generation commences. Shareholders must evaluate whether management’s capital allocation decision maximizes long-term value compared to alternative uses including returning capital to shareholders, acquiring complementary businesses, or expanding existing operations organically.

Portfolio Positioning Considerations

Investors seeking exposure to India’s semiconductor industry development have limited options through publicly listed companies. CG Power’s semiconductor initiative provides indirect exposure to this theme through an established industrial company. This may appeal to investors who seek semiconductor sector exposure but prefer companies with demonstrated operational track records.

The stock’s increased volatility following the semiconductor announcement creates trading opportunities but also increases price risk. Investors with shorter time horizons face greater uncertainty regarding near-term price movements. Long-term investors must assess whether they can tolerate volatility while the project progresses through implementation phases spanning several years.

Position sizing decisions should account for the project’s execution risks, the company’s financial leverage, and the stock’s valuation premium. Conservative portfolios might limit exposure to 3-5% of total portfolio value, while growth-oriented portfolios accepting higher risk could allocate 7-10%. These allocations should be adjusted based on individual risk tolerance and overall portfolio composition.

Diversification across multiple semiconductor-exposed companies reduces concentration risk associated with any single project’s success or failure. Complementary investments might include companies providing semiconductor equipment, materials suppliers, or electronics manufacturers that would benefit from domestic semiconductor availability. This sector-wide approach captures industry growth while mitigating single-company risks.

Monitoring Framework for Investors

Investors should establish systematic monitoring of key project milestones and financial metrics to track execution progress. Quarterly updates on land acquisition, regulatory approvals, construction progress, and partnership agreements provide indicators of whether the project proceeds according to schedule. Delays or obstacles signal increased execution risk requiring portfolio adjustments.

Financial statement analysis should focus on changes in debt levels, interest coverage ratios, and capital expenditure amounts as the project progresses. Significant deviations from announced capital expenditure plans or leverage targets may indicate cost overruns or funding challenges. These financial metrics provide early warning signs of execution difficulties.

Management commentary during earnings calls and investor presentations offers insights into technical progress, customer pipeline development, and partnership status. Questions from analysts regarding specific project aspects and management’s responses provide information beyond formal financial statements. Investors should evaluate consistency between management statements and observable outcomes.

Industry developments including government policy changes, competitive announcements, and semiconductor market conditions affect the project’s prospects. Monitoring trade publications, government announcements, and industry reports provides context for evaluating CG Power’s specific situation within broader industry trends. This contextual understanding supports informed investment decisions.

Summary and Key Takeaways

CG Power and Industrial Solutions Limited has announced plans to establish semiconductor assembly and testing infrastructure in India with capital expenditure of Rs 3,500 crores. This initiative represents the company’s entry into semiconductor manufacturing, complementing its existing electrical equipment business. The announcement generated significant market interest, reflected in elevated trading volumes and share price appreciation.

The project aligns with India’s national objectives for semiconductor industry development and qualifies for government incentive schemes including the Production Linked Incentive program. Implementation spans multiple phases through 2029, with employment generation projected at 5,000 direct positions. Success requires effective technology transfer, equipment integration, and customer acquisition to achieve projected capacity utilization and revenue targets.

Investment considerations include the project’s execution risks, capital intensity, and timeline to profitability balanced against growth opportunities in India’s developing semiconductor sector. The company’s financial position provides capacity for project funding, though specific funding structures remain to be detailed. Valuation premiums reflect market expectations regarding the project’s successful completion and contribution to future earnings.

Shareholders and prospective investors should monitor project implementation progress through quarterly updates, financial statement analysis, and industry developments. The semiconductor initiative transforms CG Power’s business model and risk profile, requiring careful evaluation of whether the strategic shift aligns with individual investment objectives and risk tolerance levels.

Frequently Asked Questions (FAQs)

1. What factors contributed to the recent CG Power share price movement?

The primary factor behind CG Power’s recent share price movement was the company’s December 15, 2024 announcement regarding its semiconductor assembly and testing facility project. According to National Stock Exchange data, the stock opened 12.8% higher on December 16, 2024, and closed with a 15.8% gain. Trading volumes reached 45 million shares, approximately four times the average daily volume, indicating heightened investor interest.

The announcement coincided with India’s national focus on semiconductor manufacturing under the India Semiconductor Mission, which provides policy support and financial incentives for semiconductor projects.

Market participants responded to the potential for CG Power to participate in India’s developing semiconductor sector, though investors should note that execution of the announced project involves multiple risk factors including technology transfer challenges, capital requirements, and timeline uncertainties.

2. What is the total investment required for CG Power’s semiconductor facility?

CG Power has announced a total capital expenditure requirement of Rs 3,500 crores for its semiconductor assembly and testing facility. According to the company’s statements, this investment is planned across three phases: Rs 1,200 crores in Phase One for land acquisition, regulatory compliance, and infrastructure development; Rs 1,800 crores in Phase Two for equipment procurement and technology transfer; and Rs 500 crores in Phase Three for production ramp-up.

The company has not disclosed the specific funding structure, which may include internal accruals, debt financing, and potentially equity issuance. Investors should monitor future announcements regarding capital raising activities. The company’s debt-to-equity ratio of 0.47 as of September 2024 suggests capacity for additional borrowing, though substantial equity dilution through rights issues or preferential placements could affect existing shareholders’ ownership percentages.

3. How does CG Power’s financial position support this semiconductor project?

Based on financial statements for the quarter ending September 2024, CG Power reported a debt-to-equity ratio of 0.47, indicating moderate leverage levels that provide flexibility for additional borrowing. Operational cash flow averaged Rs 285 crores across the three quarters reported in fiscal year 2024-25, demonstrating positive cash generation from existing operations.

The company’s interest coverage ratio of 8.3 times suggests comfortable debt servicing capacity. Working capital management shows improvement with inventory turnover increasing from 4.2 times to 5.1 times over the past year. However, the semiconductor project’s Rs 3,500 crore capital requirement substantially exceeds quarterly operational cash flows, necessitating external funding through debt, equity, or both.

The Murugappa Group’s financial resources provide additional corporate backing, though investors should evaluate the specific funding structure once announced to assess impacts on financial leverage, interest obligations, and potential equity dilution.

4. What is the expected timeline for the semiconductor facility to become operational?

CG Power has outlined a three-phase implementation timeline spanning from the announcement date through March 2029. Phase One targets completion by December 2025, focusing on land acquisition, regulatory approvals, and infrastructure construction. Phase Two targets completion by June 2027, covering equipment installation and technology transfer.

Phase Three involves production ramp-up with 75% capacity utilization projected by December 2027 and full capacity by March 2029. Investors should note that semiconductor facility development timelines frequently experience delays due to equipment delivery schedules, regulatory approval processes, technology transfer complexities, and construction challenges. The company has limited prior experience in semiconductor manufacturing, which may increase execution risks.

Quarterly monitoring of milestone achievements provides indicators of whether the project proceeds according to schedule. Delays in early phases typically cascade through subsequent phases, extending the overall timeline to revenue generation and profitability.

5. What government support is available for this semiconductor project?

CG Power’s semiconductor facility qualifies for the Production Linked Incentive (PLI) scheme for semiconductors, administered by the India Semiconductor Mission under the Ministry of Electronics and Information Technology. The PLI scheme offers financial support of up to 50% of capital expenditure for approved semiconductor projects, subject to achievement of specified investment and production milestones.

According to available information, the company has received preliminary approval for PLI benefits approximating Rs 1,750 crores. Additional benefits may include accelerated depreciation allowances under tax regulations and infrastructure support from state government authorities in Tamil Nadu. However, PLI scheme benefits are disbursed based on actual investment and production achievement, not advance payments.

The specific terms of CG Power’s PLI approval, including milestone requirements and disbursement schedules, have not been publicly disclosed in detail. Investors should monitor whether the company achieves milestones required for receiving incentive payments according to scheme guidelines.

6. How does this project compare with other Indian semiconductor initiatives?

CG Power’s semiconductor assembly and testing (OSAT) focus differs from wafer fabrication projects announced by companies like Tata Electronics. OSAT facilities generally require lower capital investment than advanced wafer fabrication plants, which can exceed $10 billion. CG Power’s Rs 3,500 crore investment is substantial but more modest than pure fabrication facilities.

The company’s existing industrial operations and customer relationships in power infrastructure sectors provide potential initial markets for power semiconductor devices. This built-in customer access differentiates CG Power from new entrants without established industrial relationships. However, CG Power faces competition from established global OSAT providers with decades of operational experience, extensive customer relationships, and proven capabilities.

Companies like ASE Technology Holding and Amkor Technology possess technological expertise and scale advantages. CG Power’s success depends on effective technology transfer from international partners, competitive pricing, and demonstrating quality levels that satisfy semiconductor industry customers’ requirements.

7. What are the major risks associated with this semiconductor venture?

Several risk categories affect the semiconductor project’s success probability. Technology risks include potential difficulties in technology transfer from international partners, equipment integration challenges, and achieving acceptable manufacturing yield rates. Low yields increase per-unit costs and delay profitability.

Execution risks arise from CG Power’s limited prior semiconductor experience, which may lead to unexpected technical problems or timeline delays. Regulatory risks encompass environmental clearances, industrial licensing, and potential changes in government incentive schemes that affect project economics. Market risks include semiconductor industry cyclicality, which could result in reduced demand when the facility becomes operational. Competitive risks involve established OSAT providers offering competitive pricing and proven capabilities.

Financial risks include potential cost overruns requiring additional capital beyond the Rs 3,500 crore estimate, possibly through dilutive equity issuance. Customer concentration risk could materialize if revenue depends heavily on few large customers whose loss would significantly impact utilization rates.

8. What is the current valuation of CG Power shares relative to industry peers?

As of the December 16, 2024 closing price of Rs 498, CG Power shares traded at a price-to-earnings ratio of approximately 28.5 times based on trailing twelve-month earnings. This valuation multiple exceeds typical electrical equipment manufacturers in India, which generally trade at price-to-earnings ratios between 18-22 times earnings. The valuation premium reflects market expectations regarding the semiconductor project’s potential future earnings contribution.

However, this premium incorporates optimistic assumptions about successful execution, timeline achievement, and profitability realization. Valuation analysis becomes complex when companies announce entry into new business segments because historical earnings may not represent future performance.

Investors should consider that if execution encounters significant challenges or timelines extend substantially, the current valuation premium may not be justified by realized outcomes. Multiple valuation approaches including discounted cash flow analysis incorporating different execution scenarios can provide more comprehensive valuation perspectives than single metrics based on historical earnings.

Author Information

Author Name: Nueplanet

Credentials: Financial Markets Analyst

Bio: Nueplanet specializes in analyzing Indian equity markets with a focus on industrial and technology sectors. With the years of experience in financial research and market analysis, Nueplanet provides fact-based insights grounded in official data from regulatory bodies including SEBI, stock exchanges, and company filings. Nueplanet analysis emphasizes objective evaluation of corporate announcements, financial metrics, and industry developments without offering investment recommendations.

About This Publication:

This analysis is intended for informational and educational purposes only. All information is sourced from publicly available documents including stock exchange filings, company announcements, government publications, and regulatory databases. Content is verified against official sources and updated regularly to maintain accuracy. This publication does not provide investment advice, stock recommendations, or personalized financial guidance. Readers should conduct independent research and consult qualified financial advisors before making investment decisions.

Commitment to Accuracy:

All data points, financial metrics, dates, and quotations are verified against primary sources including National Stock Exchange records, Bombay Stock Exchange data, SEBI filings, company investor presentations, and government ministry announcements. Any forward-looking statements or projections are clearly identified as such and attributed to their sources. Content is reviewed and updated to reflect the latest available information as of the publication date.

Disclaimer: This article is for informational purposes only and does not constitute investment advice, recommendation, or solicitation to buy or sell securities. The information presented is based on publicly available data and should not be relied upon as the sole basis for investment decisions. Stock markets involve risk, and past performance does not guarantee future results. Readers should conduct their own due diligence and consult with qualified financial advisors before making investment decisions. The author and publisher assume no liability for financial decisions made based on this content.

Sources:

- National Stock Exchange of India (NSE) – Official trading data and corporate announcements

- Bombay Stock Exchange (BSE) – Historical price data and company filings

- Securities and Exchange Board of India (SEBI) – Regulatory disclosures and compliance filings

- Ministry of Electronics and Information Technology – India Semiconductor Mission policies and updates

- CG Power and Industrial Solutions Limited – Official company announcements and investor presentations

Post Comment